- Homepage

- Information

- Thermal Production Facility Project

- Thermal Production Facility Sustainability Considerations

Thermal Production Facility Sustainability Considerations

Sustainability is the practice of meeting contemporary needs without compromising the ability of future generations to satisfy their needs. The planning process for the Thermal Production Facility focused on balancing the energy requirements and economic implications for the university with the environmental impacts of the technologies considered as future production options on the University of Florida campus. The combined heat and power approach that was chosen provides the optimal solution of available technologies while also laying the groundwork to integrate additional energy distribution concepts to provide an efficient, resilient long-term model for meeting the needs of the university.

The UF Office of Sustainability has addressed a variety of sustainability topics for the proposed project in the Climate Considerations for the New UF Central Energy Plant white paper. Additional information on sustainability aspects connected to the Thermal Production Facility project can be found below.

Electrical and Thermal Utility Infrastructure Modernization

From the beginning of the planning and design process for the Thermal Production Facility, a core goal has been to modernize the existing underground electrical and steam distribution networks on campus which have not been substantially upgraded in several decades. In conjunction with the new Thermal Production Facility, improvements to the utility distribution infrastructure will support reliability and efficiency on main campus. These types of improvements enhance the reliability of campus electrical infrastructure and systems, ensuring a stable and supportive environment in which leading researchers can innovate. These projects achieve this by addressing the following areas:

Electrical

- Simplification and Reliability: By reducing the number of voltage transformations and redundant circuits used to provide electrical service to campus, there is less potential for system failures.

- Easier maintenance: Optimizing and simplifying the UF electrical distribution network reduces the number of replacement parts that maintenance teams need to purchase and keep in-stock for quick repairs when failures do occur.

- Resilience: The planned upgrades to the campus-wide electricity distribution network will allow UF buildings to have multiple pathways for electrical connections that are core to keeping buildings online in the event of an outage or disruption. The pathways will also be optimized to remove excess redundancy that would require extra equipment and staffing to maintain.

- Efficiency and Climate: Though it is difficult to quantify, these improvements can be expected to reduce greenhouse gas emissions related to the loss of electricity distribution & transmission losses.

Steam

- Simplification and Reliability: The existing system is configured as hub and spoke, meaning that any pipe break or construction outage will affect all buildings downstream. This new infrastructure package means that steam, in most cases, can be fed from multiple directions.

- Easier maintenance: The existing steam infrastructure system is old and in places has reached end of life making maintenance difficult and dangerous. By having a properly designed system that enhances longevity of the steam infrastructure, the University should have 50 years or more of safe working conditions and easy maintenance.

- Resilience: The multiple outages and pipe breaks that the University is currently experiencing should be greatly improved by the improvements in steam infrastructure as well as replacing the Duke Energy Cogeneration plant with a new central energy plant designed specifically for the University’s thermal needs.

- Efficiency and Climate: UF’s steam distribution network has seen delayed upgrades for several years because of other budget priorities. It is estimated that the proposed upgrades in the UF steam distribution system could result in a 30% increase in efficiency.

Expansion of Solar Energy

Given that the Thermal Production Facility will have the capacity to generate up to 60% of UF’s electricity needs, UF is able to build off existing UF solar projects and pursue solar/renewable energy for the remainder of its energy needs.

On-campus

UF currently has 352 kilowatts (kW) of installed solar capacity, contributing roughly 301.5 MWh annually (0.65% of UF’s annual electricity consumption). The majority of these solar installations were funded by grant partnerships from Duke Energy Florida. UF has the potential to install up to a total of 4 MW of solar power generation on campus based on the interpretation of current statewide net metering regulations. As a public institution, UF does not have the ability to directly apply tax incentives that make solar most financially attractive. However, UF is in the process of evaluating financial partnerships that would allow the university to partner with vendors that can, making on-campus solar power more feasible.

Off-campus/purchased

Though Florida does not currently have a Renewable Portfolio Standard (RPS), UF is looking into ways to increase the amount of renewable electricity available for purchase and support larger market transition to more solar/renewable energy.

Comparison of other technologies

From the early phases of the Thermal Production Facility project development, Jacobs Engineering Group and the UF design team evaluated different technologies and configurations for feasibility to meet UF thermal (T) and electrical (E) needs:

| Thermal (T) | Electrical (E) |

| Natural gas fueled steam boilers | Purchased electricity |

| Heating hot water conversion | Solar Array |

| Heat-recovery steam generators | Wind Farm |

| Steam generated chilled water | |

| Heat recovery chillers | |

| Biomass boilers | |

| Landfill gas boilers | |

| Solar thermal hot water or steam | |

| Additional Configurations | |

| Combustion Turbine (E) with Heat-Recovery Steam Generators (HRSGs) (T) | |

| Combined cycle generation (T&E) with HRSG (T) | |

| Trigeneration of combustion turbine (E), HRSG (T) and steam generated chilled water (T) | |

Energy Savings Performance Contracts

Energy Savings Performance Contracts (ESPCs) allow UF to collaborate with industry leaders to implement energy efficiency improvements on campus, with the contracted vendor assuming most or all up-front costs for the project and recovering their investment out of the savings they provide.

Some of the major projects that have been facilitated by ESPCs include the following:

- The contract executed with Trane in 2013 to fund upgrades to the Reitz Union facility resulting in $414,000 in annual savings.

- The recently completed Veterinary Science Utility Plant in collaboration with Siemens is projected to recoup annual savings of over $690,000.

- UF’s newest ESPC will update the thermal utility system in a section of campus centered around the Law School and Housing complexes. The “Holland Law” ESPC is anticipated to generate an annual savings of $550,000/ year which is a 41% reduction in utility expenditures. The design of the project is still being finalized and currently includes an option to also install additional solar photovoltaic which converts sunlight into electricity. Even if the solar option is not selected, the Utilities Savings will be 32% and $430,000/year.

Resilience

As mentioned above, a critical component of UF’s campus infrastructure is the resilience and reliability of electrical and thermal systems. UF is a top-tier research institution, and it is imperative to the work of those on campus to ensure a safe, reliable environment in which they can conduct research and innovate.

The Thermal Production Facility offers many benefits regarding resiliency including the following:

- Islanding: With the construction of the facility, UF will be able to maintain operations independently from any larger grid or provider issues. Given the potential increased vulnerability of Gainesville to climate risks like hurricanes and tornadoes, this self-sufficiency will enable the university to provide increased reliability for key portions of campus. A striking example of the value of a university maintaining a microgrid can be explored in this case study of Princeton’s response to Hurricane Sandy.

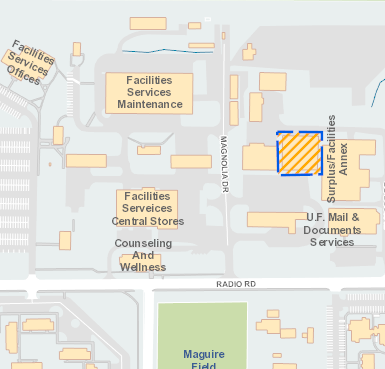

- Proximity: The facility will be located on the main campus of UF. By decreasing the physical distance that electricity and steam need to travel, this reduces the overall risk of transmission and distribution losses and the number of potential failure points in the system. Additionally, UF will be able to address any potential issues with the electrical infrastructure directly and promptly.

- Adaptability: UF has made a commitment to develop the Thermal Production Facility with the flexibility to incorporate new technologies as they become available. The facili is anticipated to initially operate on natural gas with the flexibility to incorporate other fuel sources as technology continues to advance. The turbines currently specified for the project have the potential to fuel-switch to burn renewable natural gas (i.e. biogas) as well as up to 20% pure hydrogen – both resulting in lower emissions compared to traditional fuel sources.

Ongoing context for UF Climate Action Plan & Carbon Goals

To track climate actions and targets, UF completes an annual UF Greenhouse Gas Inventory for UF’s main campus operations.

For more information about the ongoing UF CAP 2.0 process, visit the Office of Sustainability website here.

A brief history of climate action at UF is compiled on the Office of Sustainability website.